APPLICATION>Planetary & Helical Gear Units

Planetary & Helical Gear Units

Small to medium planetary and helical gear units must meet the tough challenges of specific applications such as wheel drives in agriculture and construction vehicles; and slewing drives in construction equipment and wind turbines. They operate under heavyduty cycles with heavy radial loads, shock loads and tilting movements. These gear units must provide reliable performance in highly contaminated conditions as well.

HCH bearings for planetary and helical gear units

The type and size of the bearings needed for a specific application are determined by the results of a life calculation carried out for the bearings. In close cooperation with gear manufacturers, based on extensive testing, HCH has developed calculation methods and programs that are among the most advanced in the rolling bearing industry for planetary and helical gear units.

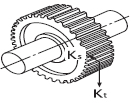

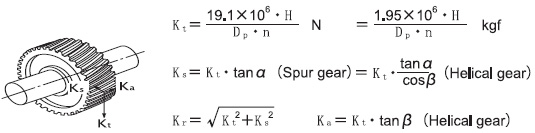

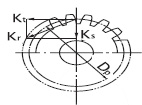

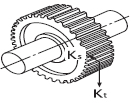

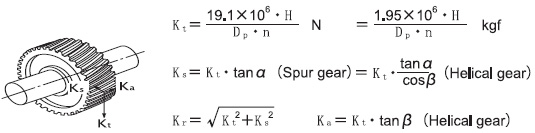

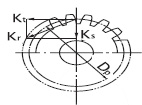

The loads operating on gears can be divided into three main types according to the direction in which the load is applied; i.e. tangential (Kt), radial (Ks), and axial (Ka). Loads acting on planetary shaft gears are depicted in the pictures.The load magnitude can be found by using or formulas:

The loads operating on gears can be divided into three main types according to the direction in which the load is applied; i.e. tangential (Kt), radial (Ks), and axial (Ka). Loads acting on planetary shaft gears are depicted in the pictures.The load magnitude can be found by using or formulas:

The loads operating on gears can be divided into three main types according to the direction in which the load is applied; i.e. tangential (Kt), radial (Ks), and axial (Ka). Loads acting on planetary shaft gears are depicted in the pictures.The load magnitude can be found by using or formulas:

where,

where,

Kt :Tangential gear load (tangential force), N

Ks : Radial gear load (separating force), N

Kr : Right angle shaft load (resultant force of tangential force and separating force), N

Ka : Parallel load on shaft, N

H : Transmission force , kW

n : Rotational speed, r/min

Dp : Gear pitch circle diameter, mm

α : Gear pressure angle

β : Gear helix angle

Because the actual gear load also contains vibrations and shock loads as well, the theoretical load obtained by the above formula should also be adjusted by the gear factor fz as shown in the table below:

Gear factor fz

HCH bearings for planetary and helical gear units

The type and size of the bearings needed for a specific application are determined by the results of a life calculation carried out for the bearings. In close cooperation with gear manufacturers, based on extensive testing, HCH has developed calculation methods and programs that are among the most advanced in the rolling bearing industry for planetary and helical gear units.

The loads operating on gears can be divided into three main types according to the direction in which the load is applied; i.e. tangential (Kt), radial (Ks), and axial (Ka). Loads acting on planetary shaft gears are depicted in the pictures.The load magnitude can be found by using or formulas:

The loads operating on gears can be divided into three main types according to the direction in which the load is applied; i.e. tangential (Kt), radial (Ks), and axial (Ka). Loads acting on planetary shaft gears are depicted in the pictures.The load magnitude can be found by using or formulas:

The loads operating on gears can be divided into three main types according to the direction in which the load is applied; i.e. tangential (Kt), radial (Ks), and axial (Ka). Loads acting on planetary shaft gears are depicted in the pictures.The load magnitude can be found by using or formulas:

where,

where,Kt :Tangential gear load (tangential force), N

Ks : Radial gear load (separating force), N

Kr : Right angle shaft load (resultant force of tangential force and separating force), N

Ka : Parallel load on shaft, N

H : Transmission force , kW

n : Rotational speed, r/min

Dp : Gear pitch circle diameter, mm

α : Gear pressure angle

β : Gear helix angle

Because the actual gear load also contains vibrations and shock loads as well, the theoretical load obtained by the above formula should also be adjusted by the gear factor fz as shown in the table below:

Gear factor fz

| Gear type | fz |

| Precision ground gears (Pith and tooth profile errors of less than 0.02mm) | 1.05~1.1 |

| Ordinary machined gears (Pith and tooth profile errors of less than 0.1mm) | 1.1~1.3 |

We will help you settle questions concerning the design of bearing mating components, lubrication and sealing, mounting and dismounting, etc.