- Main Clients and markets

- Customer Service

- Bearing Selection services

- Bearing Handling Service

- Bearing Fitting Service

- Lubrication Service

- Preload

-

Bearing cleanliness

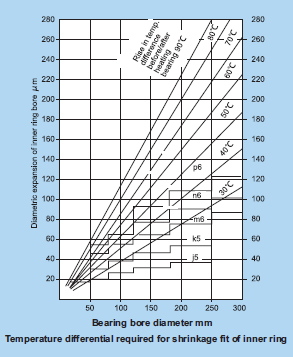

Heat mounting is recommended as an easy mounting method for bearings with tighter interference. Heating temperature can be determined from the following chart according to the specific bearing dimension and the intended interference.

|

The required relative temperature difference between the inner ring and the fitting surface depends on the amount of interference and the shaft fitting surface diameter. The chart on the left shows the relation between the bearing inner bore diameter temperature differential and the amount of thermal expansion. For applications that require a tight fit of the outer ring in housing, it may also be possible to heat the housing to expand it, allowing the bearing to install more easily. In actual mounting work, as the bearing cools, it cannot be easily mounted on the shaft. Therefore, heat the bearing to 20℃ to 30℃ higher than the lowest temperature required for mounting. For example, when a bearing with a bore diameter of 120 mm is mounted with fit n6, the maximum interference is 65um. In this case, the required heating temperature may be room temperature +50℃ as shown in the left chart, whereas the temperature must be raised an |

| additional 20℃ to 30℃ in order to easily press it onto the shaft. Consequently, the required heating temperature can be seen to be room temperature +70℃ to 80℃. | |

|

● Small bearings heating A heat lamp can also be used to heat rings, and the temperature regulated by adjusting the distance from the light to the ring. |

● Larger bearings heating

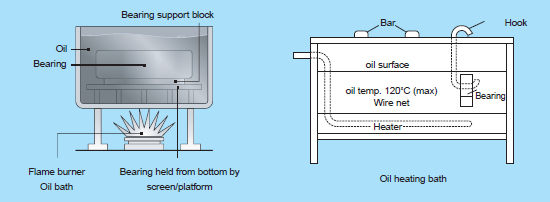

For larger bearings, you may need to use an oil bath to heat the bearing The bearing should be positioned in the center of the tank, and allowed to heat long enough to fully expand. Do not allow the bearing to come in direct contact with the heat source. The oil bath should be large enough to accommodate two to five bearings, with a sufficient amount of oil to completely cover the bearings. Precautions for use of the oil bath are shown in the follow picture. Be sure to use a wire net or equivalent device in the bath to support the bearings in the oil without allowing them to directly contact either the heater or the bottom of the bath. For easy handling, place a long bar across the top of the oil bath with an attached hook from which to suspend the bearings.

|

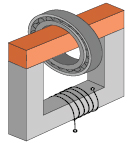

● Induction heaters |

Warning:

1. Do not heat standard bearings above 150℃ or freeze outer races below -55℃. For precision bearings, do not heat above 65℃ or freeze below -30℃.

2. When heated bearings are installed on shafts, the inner rings must be held against the shaft abutment until the bearing has been cooled in order to prevent gaps from occurring between the ring and the abutment face.

3. A bearing attached to a shaft cools rapidly, and after heating, an expanded bearing shrinks in a crosswise direction. In some cases, in order to avoid a clearance between the inner ring and shoulder, a shaft nut or other appropriate tool is applied.