- Main Clients and markets

- Customer Service

- Bearing Selection services

- Bearing Handling Service

- Bearing Fitting Service

- Lubrication Service

- Preload

-

Bearing cleanliness

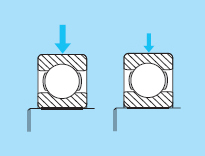

An excessive interference fit will eliminate the bearing internal clearance and cause a rise in operating temperature. A shaft interference fit expands the inner ring; similarly, a housing interference fit compresses the outer ring. It will also make the installation of the bearing more difficult and more susceptible to damage during installation. To avoid tihs problem, the following points should be considered when it is necessary to calculate the interference for an application:

● In calculating the minimum required amount of interference keep in mind that:

1) interference is reduced by radial loads

2) interference is reduced by differences between bearing temperature and ambient temperature

3) interference is reduced by variation of fitted surfaces

4) interference is reduced by hollow shaft

● Maximum interference should be no more than 1:1000 of the shaft diameter or outer diameter.

|

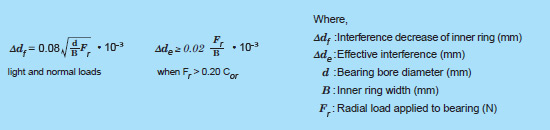

1) Magnitude of the load and Interference ( Δdf ) Under load, a slight amount of deflection or deformation of the bearing rings will occur. Subsequently, the interference fit of a bearing inner ring on its seating will be loosened with increasing load. Under the influence of rotating load the ring may begin to creep. The degree of interference must therefore be related to the magnitude of the load; the heavier the load, particularly if it is a shock load, the greater the interference fit. The required interference can be calculated using the following equations: |

|

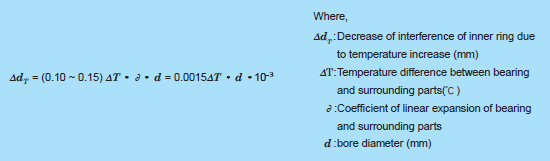

2) Temperature conditions and interference ( ΔdT )

In service, bearing rings normally reach a temperature that is higher than that of the components to which they are fitted. This can result in an easing of the fit of the inner ring on its seating. If the temperature difference between the interior of the bearing and the surrounding parts of the housing is ΔT (℃) , then the temperature difference between the fitted surfaces of the shaft and the inner ring is estimated to be about (0.1~0.15)T. Decrease of inner ring interference due to this difference may be calculated from the following equation:

3) Fitted surface and interference

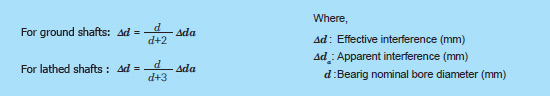

The effective interference, in other words the actual interference after fitting, is smaller than the apparent interference derived from the measured valued for the bearing bore diameter and shaft. This difference is due to the roughness or variations of the finished surfaces to be fitted, and therefore it is necessary to assume the following reductions in effective interference:

According to the equation, the effective interference of bearings with a bore diameter of 30 to 150 mm is about 95% of the apparent interference.

4) Fits for hollow shafts ( ΔH )

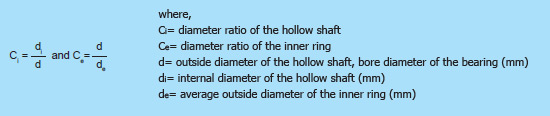

If bearings are to be mounted with an interference fit on a hollow shaft it is generally necessary to use a heavier interference fit than would be used for a solid shaft in order to achieve the same surface pressure between the inner ring and shaft seating. The following diameter ratios are important when deciding on the fit to be used.

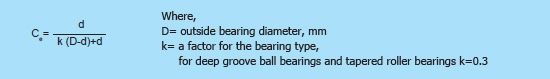

The fit is not appreciably affected until the diameter ratio of the hollow shaft Ci≥ 0,5. If the average outside diameter of the inner ring is not known, the diameter ratio Ce can be calculated with sufficient accuracy using the equation.

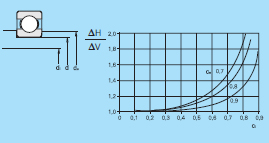

| The interference ΔH needed for a hollow steel shaft can then be determined in relation to the known interference ΔV for the solid shaft from the right chart. ΔV equals the mean value of the smallest and largest values of the probable interference for the solid shaft. The tolerance for the hollow shaft is then selected so that the mean probable interference is as close as possible to the interference ΔV obtained from the chart. |

|