- Main Clients and markets

- Customer Service

- Bearing Selection services

- Bearing Handling Service

- Bearing Fitting Service

- Lubrication Service

- Preload

-

Bearing cleanliness

Mounting with preload application is a very effective way to lessen deflection. However, under no circumstances should you ever apply a larger preload to a bearing than necessary. The amount and application method, therefore, should always be carefully observed to avoid mistakes, with due consideration for the purpose of preload.The basic pattern, purpose and characteristics of bearing preloads are shown in the following table.

● Preloading methods and characteristics

| Method | Basic pattern |

Applicable bearings |

Objects | Characteristics |

|

Fixed position preload |

|

Deep groove ball bearings |

Maintaining accuracy of rotating shaft, preventing vibration increasing rigidity |

Preload is accomplished by a predetermined offset of the rings or by using spacers. |

|

Tapered roller bearings |

Increasing bearing rigidity |

Preload is accomplished by adjusting a threaded screw. The amount of preload is set by measuring the starting torque or axial displacement. |

|

|

Constant pressure preload |

|

Deep groove ball bearings |

Maintaining accuracy and preventing vibration and noise with a constant amount of preload without being affected by loads or temperature. |

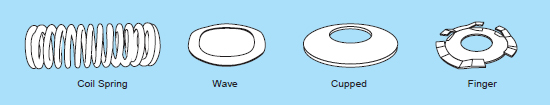

Preloading is accomplished by using coil or belleville springs. |

|

Preloading is accomplished by using washer |

Note1: Although the fixed position preload is simple, sufficient results are not possible without careful adjustment by a skilled worker. Moreover, it is difficult to accurately measure the amount of preload using this method. Therefore, the starting frictional moment and the amount of preload of a bearing must be known in advance.

Note2: In constant pressure preloading method, the size and compression of the spring can be determined from the amount of preload. In many cases, preloading by means of springs is conducted to lessen radial deflection.This type of preloading tends to misalign the spring-loaded ring and it cannot accept a reversing axial load.

● Typical springs used for preloading